The high SiC temperature resistance reaches 1650℃, and the SiC hardness is second only to diamond.

High-Performance SiC ceramics

Industries Utilizing Silicon Carbide Ceramics:

- Daily-use ceramic kilns

- Sanitary ceramic kilns

- Steel quenching furnaces

- Metallurgy

- Machinery

- Military applications (e.g., bulletproof armor)

- Mining applications (e.g., wear resistant products)

- Photovoltaic manufacturing

- Semiconductor wafer processing …

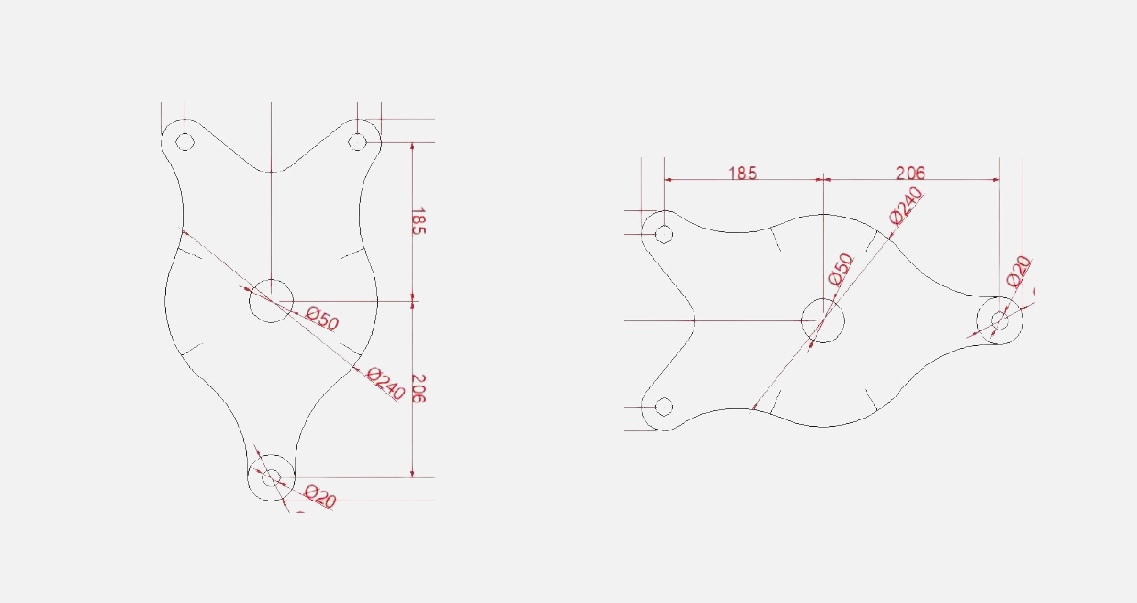

Your Vision, Our Expertise: SiC Ceramics Customization

Transforming your silicon carbide ceramic drawings into tailored, durable, and practical solutions.

High-purity SiC powder: lightweight with diamond-like strength.

SiC Powder

SiC plates resist heat, wear, and chemicals for kiln and more industry.

SiC Plate

SiC Grinding and Linings suit mining and wear industries.

SiC Grinding & Linings

SiC nozzles resist heat and wear for refractory applications.

SiC Nozzle

SiC heating elements resist heat and wear for high-temperature applications.

Heating Elements

SiC rods and bars resist heat and wear for industrial applications.

SiC Rod & Bar

SiC crucibles resist heat and wear, ideal for glass and metallurgy.

SiC Crucibles

SiC boats resist heat and wear, for semiconductors and photovoltaics.

SiC Boat

SiC sealings and rings resist wear and corrosion, ideal for pumps and valves.

SiC Sealings & Rings

Kiln furniture resists heat,for daily, sanitaryware, and electronics ceramics.

Kiln Furniture

SiC grinding balls resist wear, ideal for mechanical and industrial applications.

SiC Grinding Ball

SiC beams and rollers are durable and ideal for kilns and furnaces.

SiC Beams & Rollers

Industry Applications of Silicon Carbide

sic applications

Certified Quality

Our Workshop

Exhibition Moments

ceramic japan exhibition

exhibition

Italian Ceramic Exhibition

Vietnam Ceramics Exhibition

Guangzhou International Ceramic Fair

Shanghai International Ceramics Fair

Italian Ceramics Exhibition

Vietnam Ceramic Exhibition

Guangzhou International Ceramics Fair